LM3 Collaborative Robot

Product Introduction

The LM3 is a compact lightweight collaborative robot with a lightweight body and a simple appearance design with a maximum load of 3kg at the end. LM3 has strong versatility and collaboration, can be equipped with different types of end effectors to complete corresponding assembly, handling and other operations, and has a wide range of application prospects in life services, light industry logistics, education and development scenarios. The code editor and timeline editor tailored for the robot control system of Lebai team reduce the cost of users using and controlling robots, and realizes an easy-to-learn and easy-to-use operating experience; at the same time, it provides a rich control interface protocol at different levels, providing more convenience for the implementation of robot integration solutions.

Product Features

Lightweight Body

The total weight of the LM3 robot body and control box is less than 14kg, making it more convenient to use, install, and deploy.

Safe and Reliable

LM3 supports collision safety protection, when an object is detected in the collision, the robot immediately stops/pauses, providing timely and effective safety guarantee for the surrounding people/objects.

Unlimited Joints

All joints of LM3 can achieve unlimited movement range, providing more possibilities for robot application scenarios.

Interactive Personalization

LM3 supports scene and action style settings, providing various human-machine interaction methods such as voice, light, hardware button operation, improving the robot's usability and application efficiency.

Simple and Easy to Use

No teaching box required, LM3 uses pull/drag teaching, and can be easily operated through a web browser or APP. The time axis editor developed by the LM3 team provides a low-threshold scenario editing experience.

High Extensibility

LM3 supports a rich control protocol interface, which is convenient for integration and quick support for external systems and devices, and can also better control third-party extended I/O devices.

Visual Programming Software

Lebai Robot has developed a code editor (supporting Python, Lua, C#, javascript, etc.) and a time axis editor for the robot control system, which reduces the cost of user use and control of the robot, and realizes an easy-to-learn and easy-to-use operation experience; at the same time, it provides a rich control interface protocol at different levels, providing more convenience for the implementation of robot integration solutions.

API Control Documentation: https://help.lebai.ltd/api/

IO Control Documentation: https://help.lebai.ltd/sdk/io/

Modbus Documentation: https://help.lebai.ltd/sdk/web/

Visual Programming Software

Simple Teaching

Application Cases

Smart Harvesting Application

Combined with visual recognition technology, LM3 collaborative robot can accurately identify and harvest mature fruits, significantly improving agricultural production efficiency.

Laboratory Grab and Detection

LM3 performs precise grabbing and detection tasks in the laboratory environment, ensuring the accuracy and consistency of the experimental process.

LM3 Python SDK Programming Guide

LM3 Python SDK Programming Guide

Detailed Specifications

Degree of Freedom

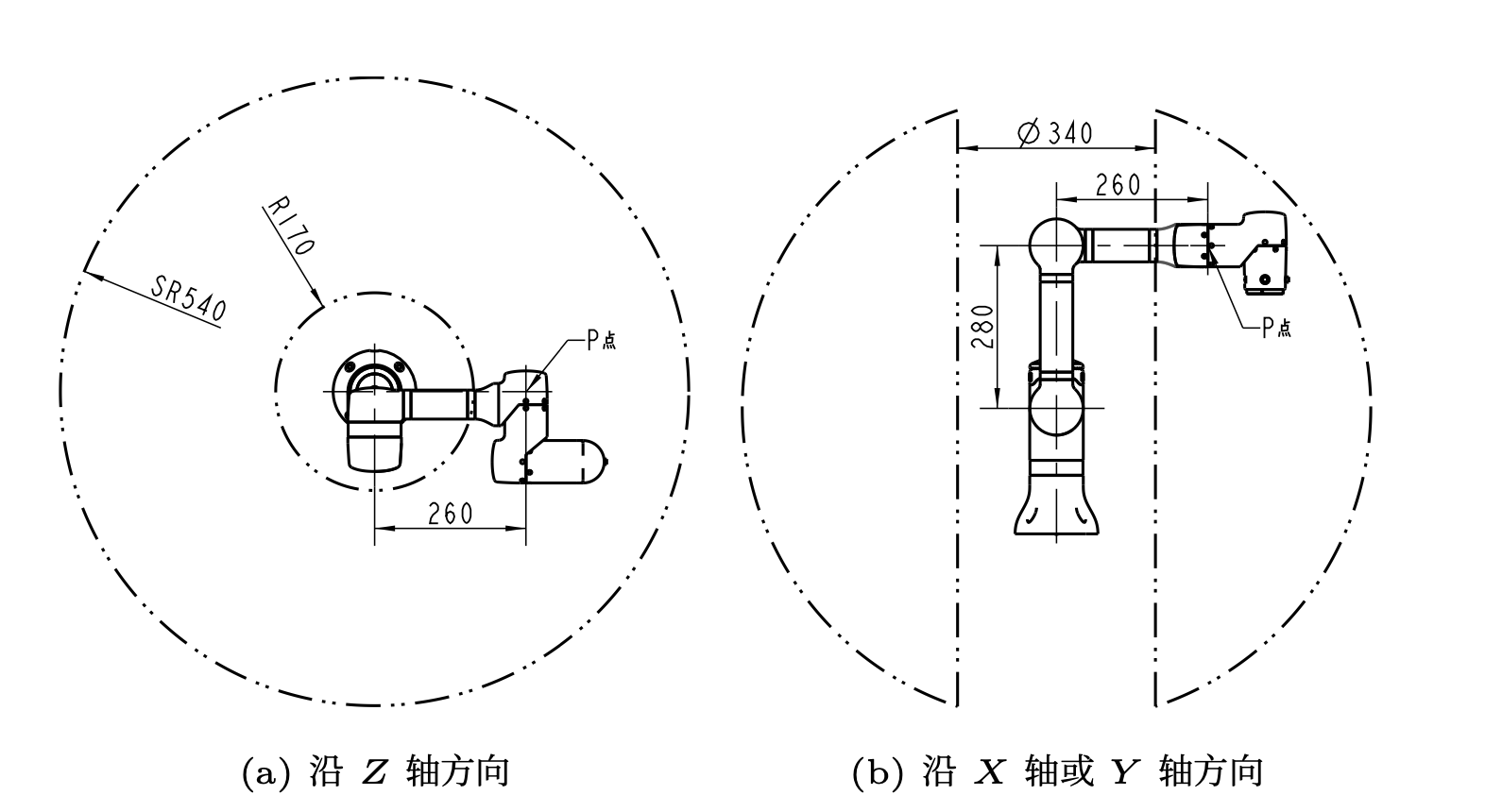

Work Radius

Effective Load

Repeatability

Body Weight

Arm Weight

Basic Parameters

Joint Movement Range and Maximum Speed

| Joint | Movement Range | Maximum Speed (°/s) |

|---|---|---|

| Joint 1 | Unlimited | 180°/s |

| Joint 2 | Unlimited | 180°/s |

| Joint 3 | Unlimited | 180°/s |

| Joint 4 | Unlimited | 180°/s |

| Joint 5 | Unlimited | 180°/s |

| Joint 6 | Unlimited | 180°/s |

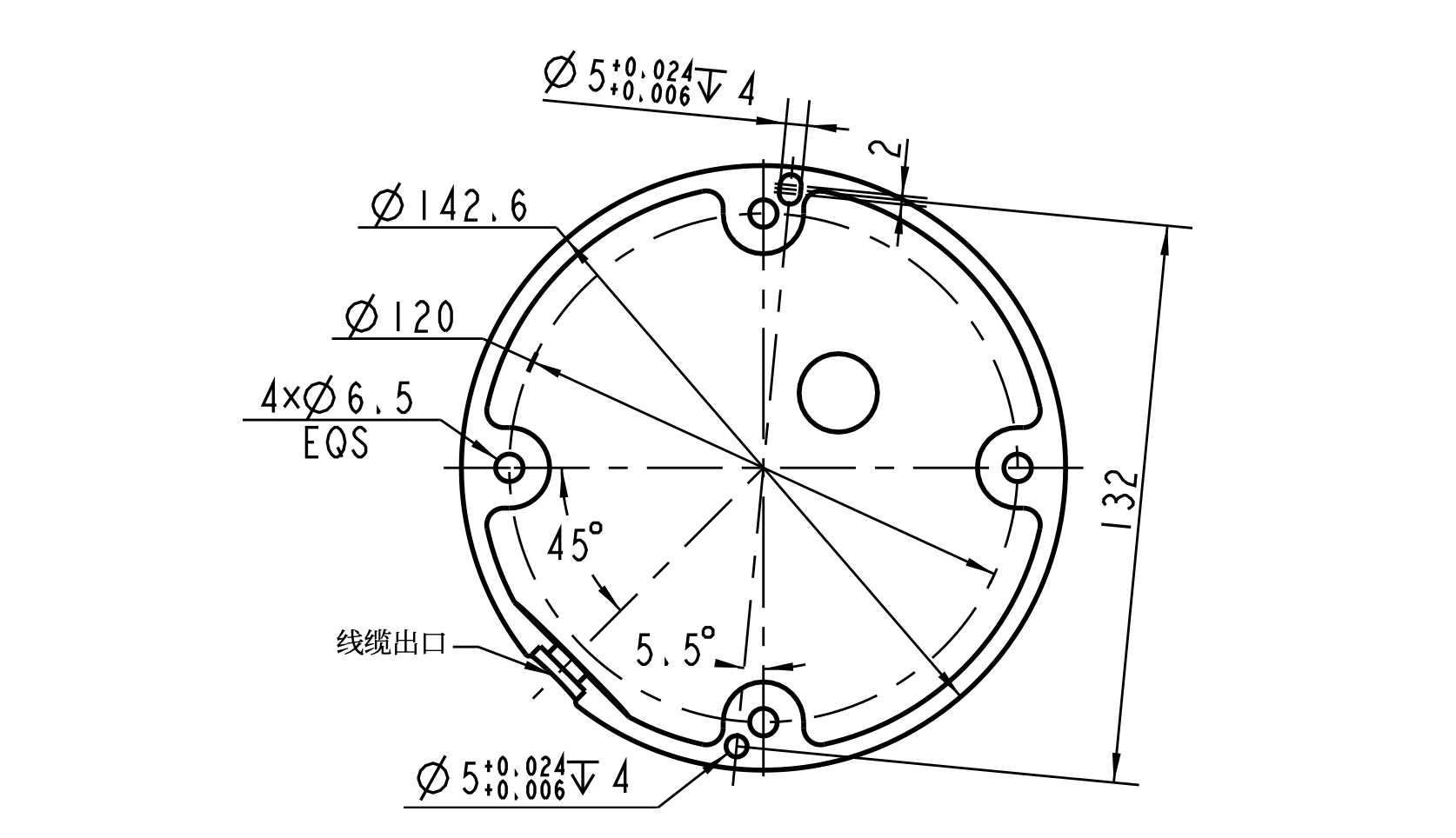

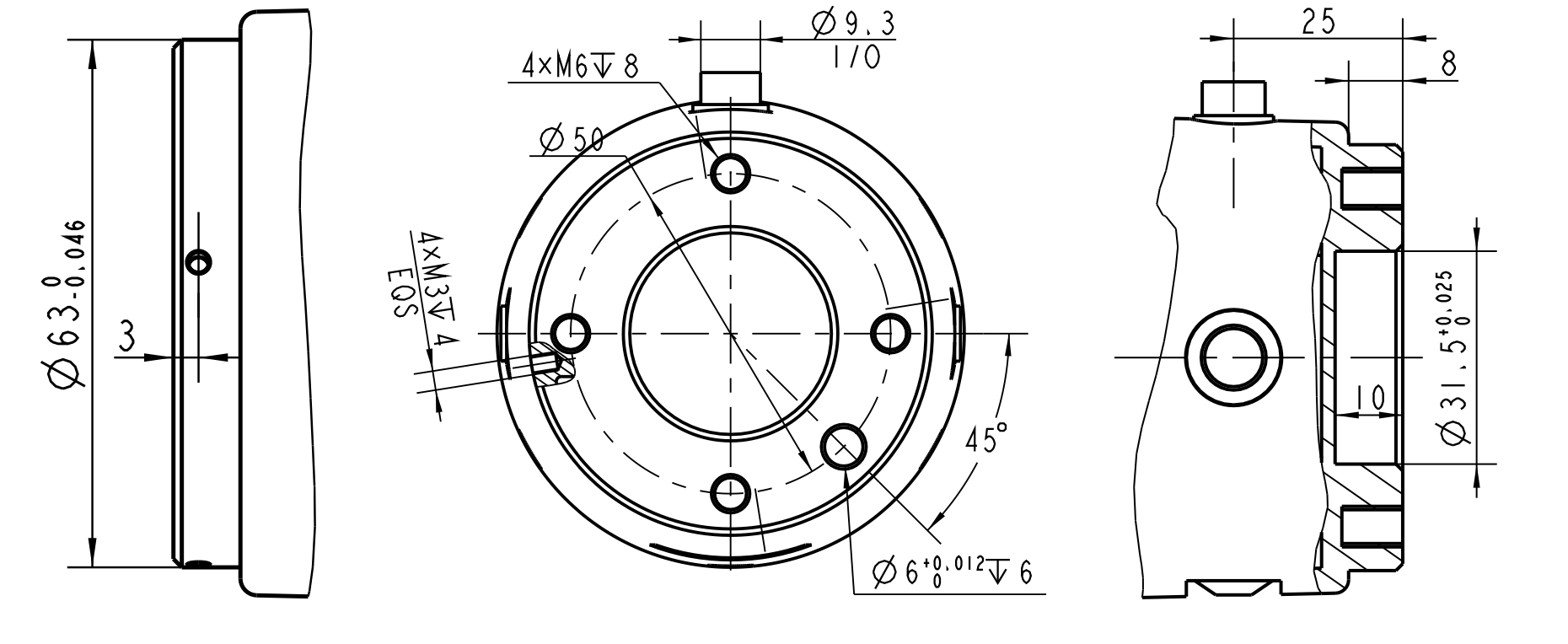

Installation Interface

Movement Range

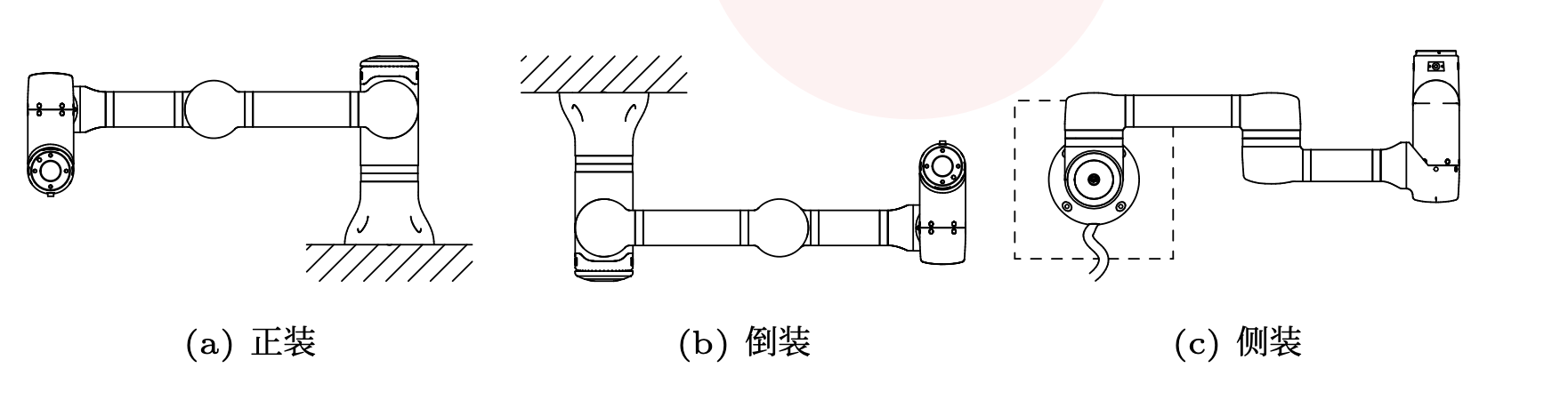

Installation Method

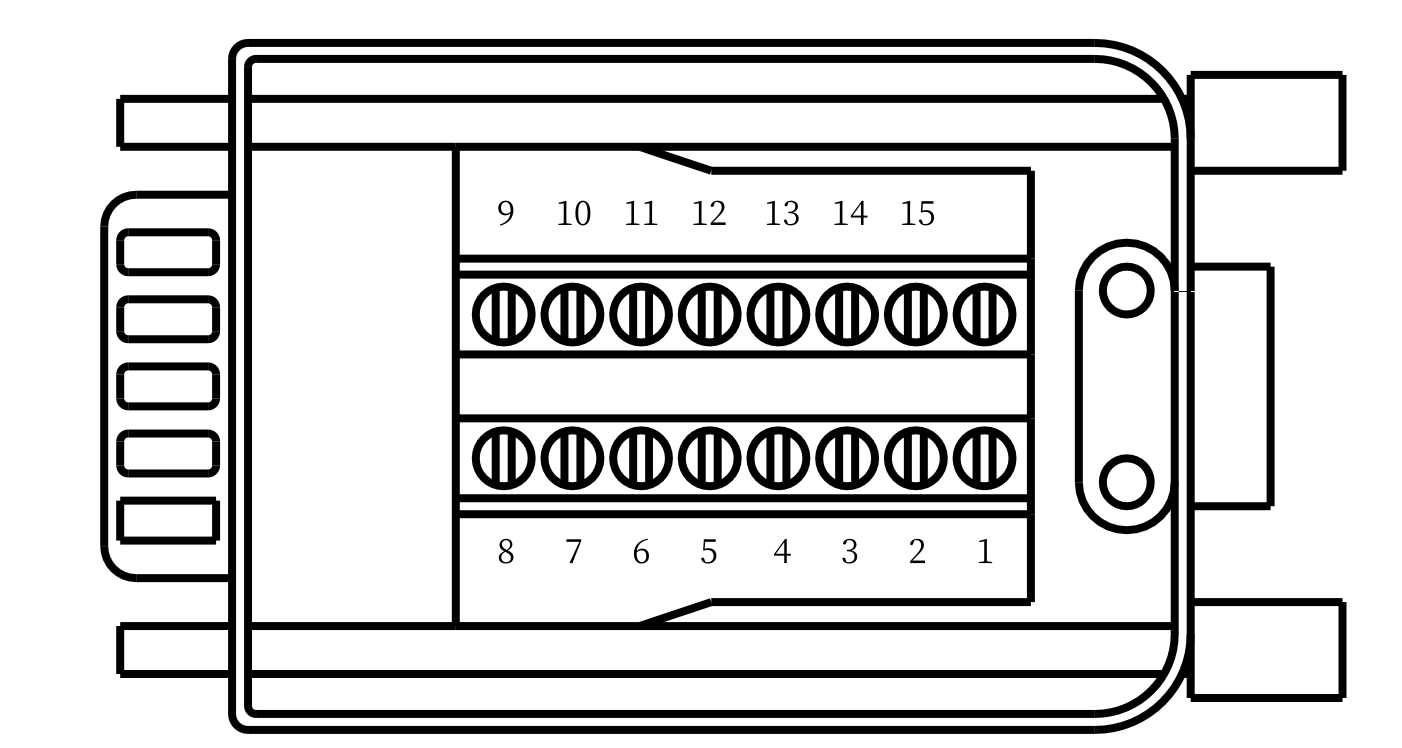

Control Box I/O Interface (DB15)

Flange I/O Interface